A pioneer in micro-3D printing, Paul Dalton is the second recipient of the Bradshaw and Holzapfel Research Professorship In Transformational Science and Mathematics

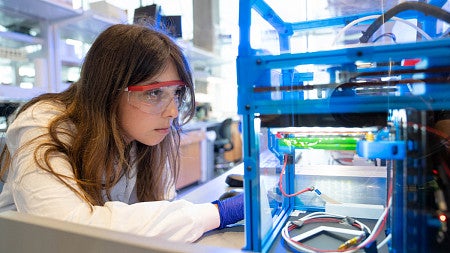

Through his research and innovation activities in the Department of Bioengineering at the Phil and Penny Knight Campus for Accelerating Scientific Impact, materials scientist and micro 3d printing pioneer Paul Dalton is helping to re-envision the future of advanced biomedical materials manufacturing. As the newly named Bradshaw and Holzapfel Research Professor In Transformational Science and Mathematics, Dalton will be able to further push the limits of high-resolution fabrication.

“I’m tremendously grateful for the vote of confidence and the opportunities this endowed position affords,” Dalton said. “There is pervasive inequality with advanced research equipment access at higher education institutions that this valuable funding can directly address.The Bradshaw and Holzapfel Laboratory at University of Oregon has always kept a laser-focus on the application of science to solve real-world problems, and I am inspired to advance the highly-applied field of open-access 3D printing in their name and follow in their esteemed footsteps.”

Dalton is the second recipient of the endowed professorship following UO chemist Darren Johnson. The position was established by William Bradshaw and Christina Holzapfel in the UO Institute of Ecology and Evolution. It is awarded based on merit as evidenced by prior publications in top-tier referred journals and on evidence of future transformational research.

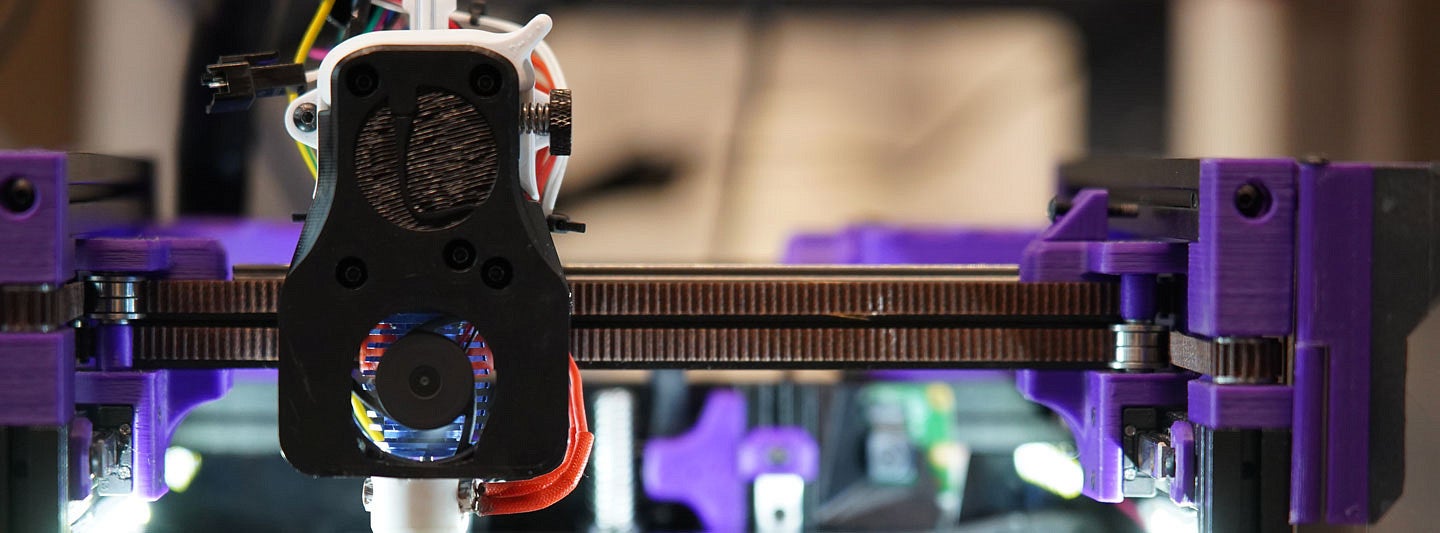

Dalton has published more than 100 research articles in journals that include Advanced Materials Progress in Polymer Science and Nature Materials and is credited with inventing and developing melt electrowriting as a distinct class within 3D-printing. He made waves with a recent research paper that provided an instruction plan for affordable, open-source microscale 3D printers. Dalton is on a mission to make the technology — which can be employed in tissue engineering, cancer research and biofabrication among other uses — accessible to researchers around the world

Dalton will hold the professorship for five years. The award will support a sustained hardware outreach campaign for the Dalton lab to design, build and promote advanced open-source 3D printers. This includes support of undergraduate, graduate, and post-doctoral students in the Dalton laboratory to attend and engage with the community on 3D printing.

“Building on the outstanding and eminently modifiable Voron 3D printer, we can produce 3D printers with capabilities well-beyond their original specifications,” Dalton said. “This includes nanoscale 3D printing, where 500 nanometer fibers are produced. That’s around 1/100th the diameter of a human hair. We are excited to apply these printers for advanced research, and to do this in an affordable way.”

Researchers in the Bradshaw and Holzapfel Laboratory are focused on the genetics of blood-borne diseases, climate change, biological timing mechanisms and the broader question of the molecular genetic basis of evolutionary change in natural populations. Their primary research organism is Wyeomyia smithii, a small mosquito that develops only within the water-filled leaves of the purple pitcher plant. Researchers conduct genetic studies in three variable climate rooms at the UO maintained with state-of-the-art, computer-driven controls that allow scientists to program the natural environment of any region of Earth, from the tropics to the poles. In 2007, their lab was designated by the National Science Foundation (NSF) as being one of ten labs across all disciplines from astrophysics and engineering to nanoscience and earth sciences that best represent NSF’s primary mission of transformational discovery.

Holzapfel and Bradshaw said they established the endowed professorship as another way to give back to the UO and foster “a community of scholars.”

— Sept. 1, 2023

Header Image: Photo collage with Paul Dalton standing before a false-colored image of microfiber 3D printed scaffold